For the solidification of iron calculate the critical radius – The solidification of iron is a complex process involving the formation and growth of solid crystals from a liquid melt. Understanding the critical radius, the minimum size at which a stable solid nucleus can form, is crucial in controlling the solidification process and achieving desired material properties.

This article delves into the concept of critical radius in iron solidification, exploring its mathematical formulations, influencing factors, and implications for nucleation, growth, and the resulting microstructure. It also discusses practical applications of critical radius calculations in industrial settings.

Critical Radius for Solidification

The critical radius for solidification is the minimum radius of a stable nucleus that can form during the solidification process. If a nucleus has a radius smaller than the critical radius, it will redissolve into the liquid phase. If it has a radius larger than the critical radius, it will continue to grow into a solid phase.

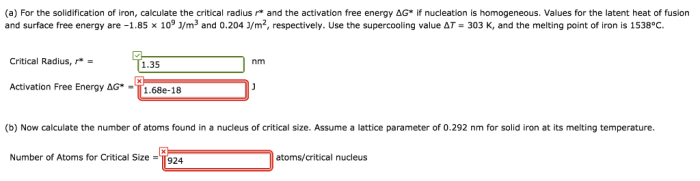

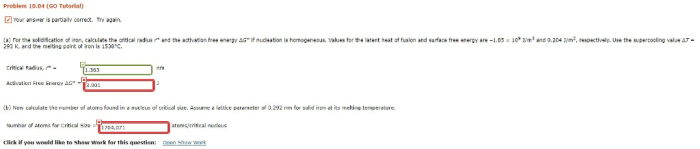

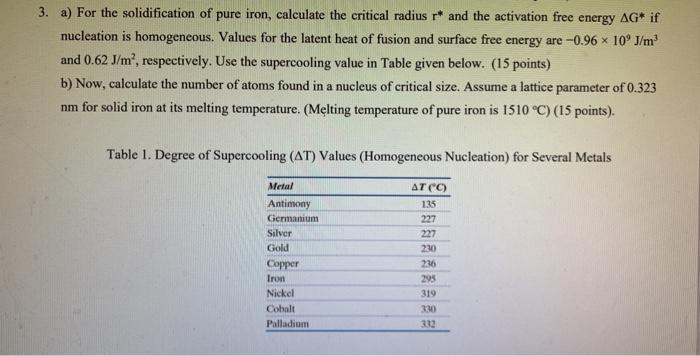

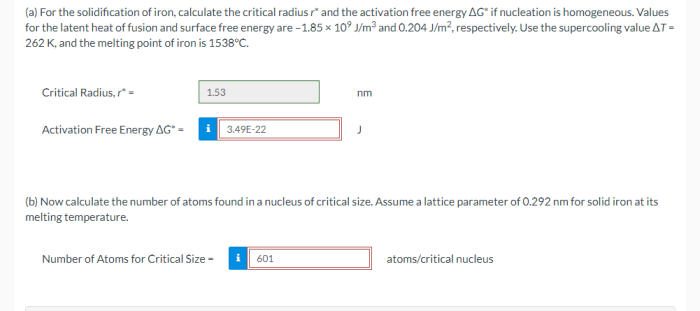

The critical radius can be calculated using the following equation:

rc= 2γ slT m/(ΔH mρ sL f)

where:

- r cis the critical radius

- γ slis the solid-liquid interfacial energy

- T mis the melting temperature

- ΔH mis the heat of fusion

- ρ sis the density of the solid phase

- L fis the latent heat of fusion

The critical radius is affected by a number of factors, including temperature, composition, and cooling rate. The higher the temperature, the smaller the critical radius. The higher the concentration of solute atoms, the larger the critical radius. The faster the cooling rate, the smaller the critical radius.

Nucleation and Growth, For the solidification of iron calculate the critical radius

Nucleation is the process by which a solid phase forms from a liquid phase. Growth is the process by which a solid phase increases in size. The critical radius is related to the nucleation and growth process in that it determines the minimum size of a nucleus that can grow into a stable solid phase.

There are two types of nucleation: homogeneous nucleation and heterogeneous nucleation. Homogeneous nucleation occurs when a nucleus forms in a pure liquid phase. Heterogeneous nucleation occurs when a nucleus forms on a surface or impurity in the liquid phase.

The type of nucleation that occurs depends on the surface energy of the solid-liquid interface. If the surface energy is high, homogeneous nucleation is more likely to occur. If the surface energy is low, heterogeneous nucleation is more likely to occur.

Solidification Microstructure

The solidification microstructure is the structure of the solid phase that forms during solidification. The solidification microstructure is influenced by a number of factors, including the critical radius, the cooling rate, and the composition of the liquid phase.

There are a number of different types of solidification microstructures that can form in iron. These include:

- Dendritic

- Cellular

- Equiaxed

- Columnar

The type of solidification microstructure that forms depends on the critical radius, the cooling rate, and the composition of the liquid phase.

Applications

Critical radius calculations are used in a number of applications in the solidification of iron. These include:

- Controlling the solidification microstructure

- Improving the properties of iron castings

- Predicting the solidification behavior of iron alloys

Critical radius calculations are an important tool for understanding and controlling the solidification of iron.

Expert Answers: For The Solidification Of Iron Calculate The Critical Radius

What is the critical radius for solidification?

The critical radius is the minimum size at which a stable solid nucleus can form in a liquid melt during solidification.

How is the critical radius calculated?

The critical radius can be calculated using mathematical equations that consider factors such as temperature, composition, and cooling rate.

What factors affect the critical radius?

The critical radius is influenced by temperature, composition, cooling rate, and the presence of impurities or defects.